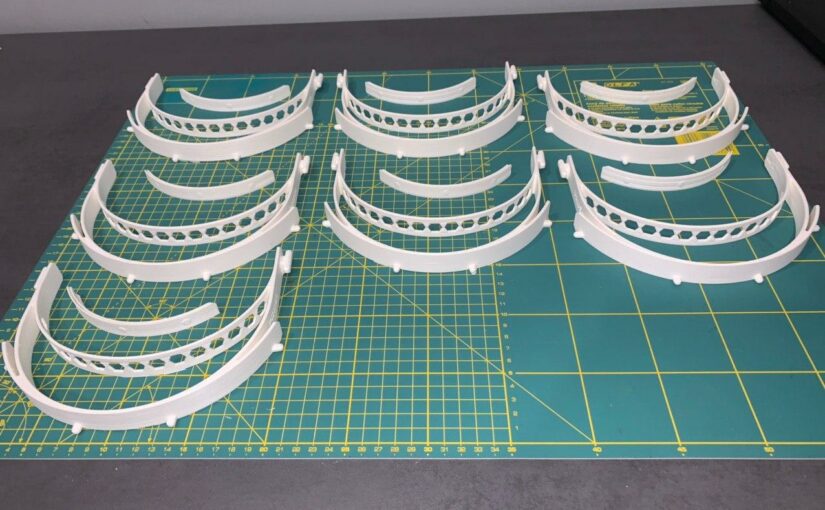

CR-10 Max from Creality is a large printer. One thing i don’t like about it is the printing surface. I’m used to the comfort of Prusa flexible sheet in order to get the models removed easily from the build plate. And on Creality sometimes prints stick too well . So well that i had to take the build plate out and remove them. When printing shields this is annoying and time consuming. So i decided to give a try to WhamBam Flex system . Took around 10 days to get it. I didn’t found any tutorials on how to do it for CR-10 Max so i decided to create a how to so other if they are interested to have a reference point. Took me almost 20 minutes to install it. So here is how to install whambam on creality CR-10 Max:

There are 2 parts of the video ( joined them ) (when shooting the video i forgot to remove the last protective sheet , and after i actually tried to print PLA didn’t stick at all . I figured out what was wrong and added a short video at the end of the first one ) .

So I hope you find this useful.